Our Products

417 Series

The new purpose-built New Zealand model ELTEC 417 series is an extra-heavy-duty tracked Harvester coming in at a 41tonnes(base only) and built with the Kiwi logger in mind, it features a purpose-built cab designed for NZ safety regulations that is the most spacious on the market, a heavy duty corner post, additional guarding and a 300mm cab riser.

This machine offers more hydraulic performance than other competitors and is designed to handle a big wood processing head with ease. With the tractive effort and slew power provided this machine will also be able to prove itself in all cutover applications as well making it the ultimate straight out the box purpose built forestry package, Whether it be cutting to length on the landing or felling and bunching in the cutover this machine will handle the job no matter what size timber or terrain is put in front of it!

317L Series

This ELTEC heavy-duty log loader is designed and purpose-built to deliver high productivity, consistent with the demands of a heavy-duty 24 hour-a-day, 7 day-a-week bulk loadout machine.

But the 317L story does not end there – it also has the ability to easily throw all models of harvester heads off the end of it and provides superior vision – pushing safety, operator productivity and accuracy to the next level.

310 Series

This ELTEC heavy-duty tracked feller-buncher is the biggest tracked feller/buncher on the market designed and purpose-built to deliver high productivity, consistent with the demands of a 24 hour-a-day, 7 day-a-week operation.

Coming in at 36 tonne without the attachment, this machine will provide a go to carrier base for all applications whether a big wood harvesting head or a directional felling head be your weapon of choice – no standing timber or terrain will stand a chance.

270 Series

This ELTEC short tail swing tracked, feller-buncher is designed and purpose-built to deliver high productivity, consistent with the demands of a 7 day-a-week, selective harvesting or final felling applications.

220 Series

This ELTEC zero tail swing tracked, feller-buncher is designed and purpose built to deliver high productivity, consistent with the demands of a 7 day-a-week, selective harvesting or final felling applications.

Product Features

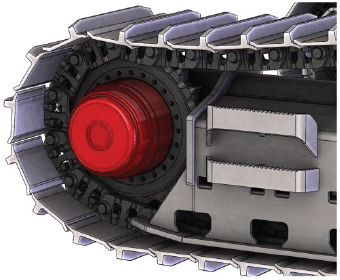

TRACTIVE EFFORT

- High walker forestry undercarriage.

- Integral guarding and ramp angles at each end.

- Sealed front idlers.

- Heavy-duty tensioner.

- High torque planetary track with failsafe disc brakes.

- Variable displacement piston motors w/integrated counterbalance valves.

D6: 85 000lbs / 35 555kg

D7: 100 000lbs / 45 359kg

SWING DRIVE / TORQUE / BEARING

- The most powerful in its category.

- Torque: 115.2kNm (85 000 lb-pi).

- Continuous rotation, max 8.0 tr/min.

- Bearings: 1400mm (55po) in diameter.

- Internal gear in grease bath.

- Standard: 85 000lbs-lb / 115.2kNm

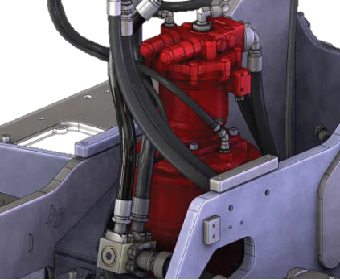

MAIN PUMPS

- Hydraulic system operated by Linde VW25 Series valves, allowing a maximum

flow to each function. - Main block located behind boom allowing an easy access, thus easy maintenance.

- Valves configurations have been designed specifically for feller-buncher or harvester

operations.

CONTROLS

- Sauer Danfoss PLUS ONE control system allowing operator to personalize

functions. - Right hand side full keyboard.

BOOM

- Designed to sustain any hard demand and maximum lifting capacity at maximum reach.

- Offered in many configurations in order to adapt to any kind of forestry operation.

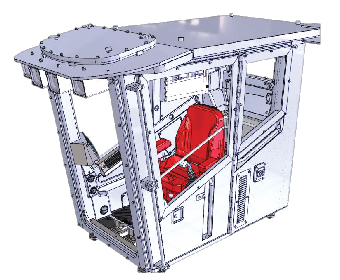

CAB

- Certified under ROPS – FOPS – OPS regulation.

- Three emergency exit: left side door, rear window and the roof

window. - Assembled on eight rubber mounts reducing tremendously engine vibrations.

- THE most spacious in the industry with room for an assistant operator behind the operator’s seat.

- With customer satisfaction in mind, a lot of storage facilities been added to accommodate operator.

- Radio and CD player w/remote control is included.

- Multiple air duct openings are located at strategic places for maximum operator comfort.

- Operator’s seat is supplied with an air compressor for easy adjustment.

- The front glass covers the entire cab front face. With a 32mm – 1.25 inch polycarbonate glass.

- Left side window also offers optimal peripheral vision.

- A full console located at the right side of the operator.

- Radio and CD player w/remote control is included.

ENGINE

- ELTEC machines are powered by Tier 4 Interim QSL9 CUMMINS engine.

The QSL9 engine is 2017 EPA approved using an exhaust gas recirculation

system without DEF. - Cooling system has been developed simultaneously for the Tier 4

Interim and Tier 4 Final. - All engine compartments have been adapted for a maximum air fan flow.

ECU is totally synchronized with main pumps for anti stall. - Full access to the engine and components for easy maintnenance.